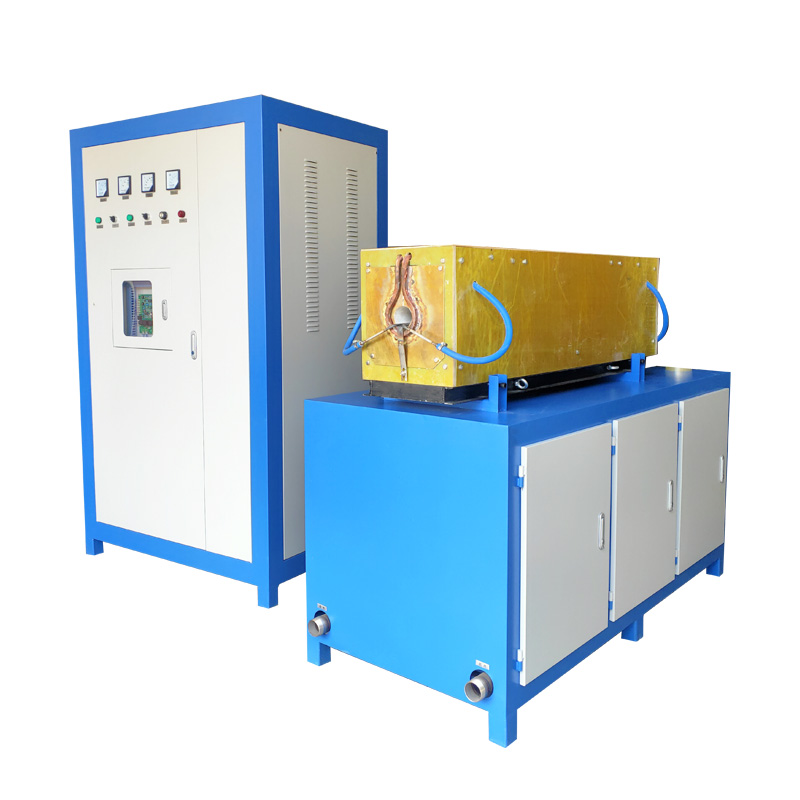

Main technical parameters of 160KW super audio quenching equipment:

modelRAC-160 | input power | 160KW |

|

Input voltage | 342V-430V | Max input current | 230A |

Oscillation frequency | 15-30KHZ | Cooling pressure | 0.1-0.3Mpa |

Host volume660×460×1420mm | Transformer volume | 600×426×435mm |

|

Host weight | 90±5%kg | Transformer weight | 80±5%kg |

water temperature protection | 50℃ | effectiveness | 100% |

Main technical advantages:

1. Using Siemens IGBT power devices and unique inverter technology, full-load continuous rate design, 24-hour operation at maximum power, high reliability guarantee;

2. The automatic control type can adjust heating time, heating power, holding time, holding power and cooling time, which greatly improves the quality of heating products and the repeatability of heating, and simplifies the operation technology of workers;

3. Light weight, small size, simple installation, just connect the three-phase power supply, water inlet and outlet, and it can be completed in a few minutes;

4. Small footprint, simple operation, can be learned in a few minutes;

5. It is especially safe to avoid the danger of high voltage electric shock.

6. The heating efficiency is as high as 90%, the energy consumption is only 20%-30% of the old electronic tube equipment, almost no electricity is needed in the standby state, and it can work continuously for 24 hours.

7. The sensor can be freely and quickly disassembled and replaced, and the ultra-fast heating greatly reduces the oxidation deformation of the workpiece.

8. A new environmentally friendly product that replaces the heating of dangerous substances such as oxygen, acetylene, and coal, and it is safer to produce without an open flame.

9. The equipment has complete automatic protection functions such as overcurrent, overvoltage, water shortage, and shortage, and is equipped with a fault self-diagnosis alarm system.

10. The equipment has the control function of constant current and constant power, which greatly optimizes the heating process of metal, realizes efficient and fast heating, and gives full play to the superior performance of the product.

Application fields of super audio quenching equipment 160KW:

1. Heat treatment application:

1. High frequency quenching on the surface of gears (pulley shaft, drive wheel);

2. Quenching heat treatment and quenching machine tools for shaft parts;

3. Surface quenching of high frequency, medium frequency and super audio frequency of spline shaft (internal tooth spline);

4. Intermediate frequency surface quenching heat treatment for automobile axle shafts;

5. High frequency surface quenching heat treatment of boring bars;

6. Multi-station high frequency quenching heat treatment of machine tool spindle;

7. High frequency surface quenching of drill pipe and core pipe;

8. Surface induction hardening of straightening rollers with intermediate frequency and super audio frequency;

9. High-frequency induction surface quenching of the inner hole of sleeve-type parts;

10. High frequency surface quenching of machine tool guide rails;

11. High frequency surface quenching of large modulus worm;

12. Ultrasonic penetrating quenching of bearing rings;

13. Induction quenching heat treatment of automobile brake shoes;

14. The overall high frequency induction hardening of the sprocket;

15. Continuous induction quenching of the inner wall of the pump pipe of the concrete pump truck;

16. Induction hardening of engineering machinery pins, high frequency hardening of pins;

17. High-frequency heat treatment and machine tools of shock absorber connecting rods of automobiles and motorcycles;

18. Ultrasonic heat treatment of transmission shaft;

19. Induction heat treatment of ball head pin ball head;

20. High frequency continuous quenching heat treatment of toothed screw

21. High-frequency quenching of lifting ring lifting clip rigging.

22. High-frequency quenching heat treatment of agricultural machinery parts.

Second, the scope of application of diathermy forging:

1. Application of ribbed induction annealing production line;

2. Heating and burning through the hot upsetting production line of round steel bar and steel column;

3. Induction heating of square steel;

4. The diathermy of the whole iron rod;

5. Red forging of standard parts (nuts and bolts);

6. Partial through-fire forging forming of pipes;

7. Hot forging of cold-drawn solid section steel, hot upsetting of the tie head of cold-drawn seamless steel pipe;

8. Induction hot upsetting of drill pipe ends;

9. Heating forging of automobile maintenance tools (socket wrenches);

10. Heating, stamping and bending of high-voltage power transmission and power line tower angle steel plates;

11. On-line warm upsetting forging of copper bars;

12. The application of heating and warm upsetting in the hot upsetting production line of the automatic steel ball and steel column upsetting machine.

13. Hot forging of rivets, spring bars and road studs for railway accessories

14. Heating of supporting accessories such as circlips and U-shaped cables;

15. Heating ears of leaf springs, etc.

浙公網安備 33038102331513號

浙公網安備 33038102331513號