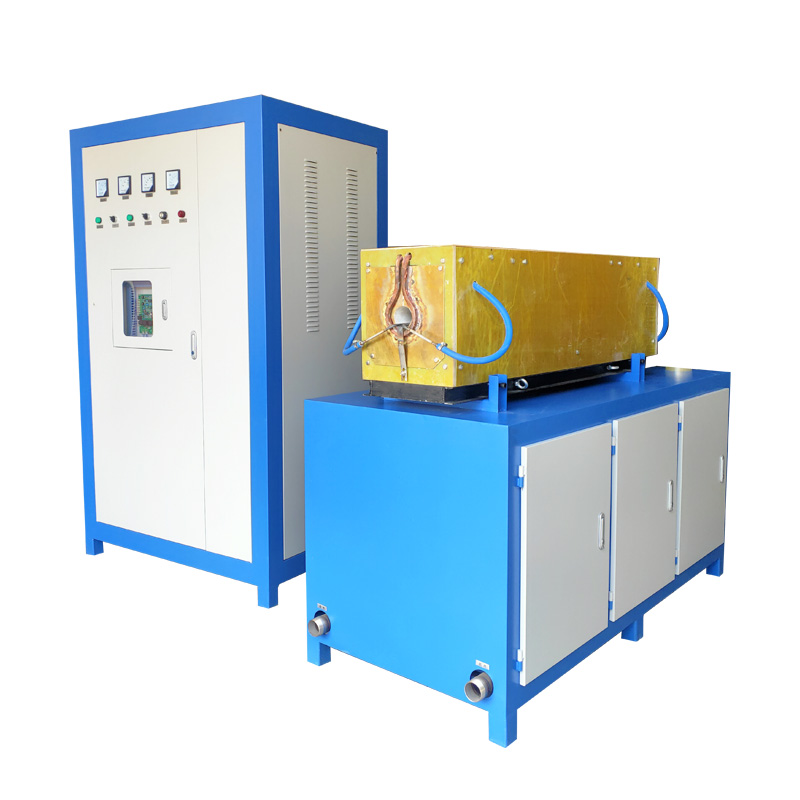

15KW small high-frequency welding equipment induction heating brazing machine is a new type of induction heating equipment, mainly used for metal pipe welding, alloy tool welding, carbide saw blade welding, diamond saw blade welding, marble saw blade welding, etc. ......

The specific functions and uses are as follows:

1. 15KW small high-frequency welding equipment induction heating brazing machine can be used for welding metal pipe fittings, such as: copper pipe and copper pipe, copper pipe and steel pipe, steel pipe and steel pipe, steel pipe and iron pipe, copper pipe and iron pipe, iron pipe Butt welding, plug welding, sleeve welding, etc. with iron pipe, copper pipe and aluminum pipe, steel pipe and aluminum pipe, aluminum pipe and aluminum pipe, etc., for welding metal pipe fittings (recommended to use silver welding ring welding) advantages:

1. Induction heating is fast and efficient

2. Compared with oxygen welding, the cost of energy saving and electricity saving is low

3. Small oxidation area

4. After welding, the appearance is exquisite, firm and full

5. The heating is uniform, so there is no missing soldering and missing solder joints

2. 15KW small high-frequency welding equipment Induction heating brazing machine can be used for welding of alloy tools, such as: alloy turning tools, milling tools, planing tools, saw blades, reamers, boring tools, etc. Advantages for welding alloy knives:

1. Induction heating is fast and efficient

2. Just place the silver solder piece between the cutter head and the base to locate it

3. Energy saving and low cost

4. Small oxidation area

5. Beautiful appearance after welding

6. The heating is uniform, so there is no missing soldering and missing solder joints.

3. 15KW small high-frequency welding equipment induction heating brazing machine can be used for carbide saw blade welding, diamond saw blade welding, marble saw blade brazing, woodworking saw blade brazing, grass cutting blade welding, aluminum cutting blade welding, etc. The advantage is:

1. Efficient and fast welding teeth, 1-5 seconds per tooth;

2. Good repeatability, each tooth has good repeatability;

3. The heating is fast and uniform, which can effectively prevent the embrittlement and fracture caused by local overheating of the saw teeth, and also prevent the tooth loss caused by incomplete penetration;

4. It can weld saw blades with high performance and high hardness saw blades, which cannot be welded by resistance welding.

5. Low power consumption (2-3kw/h)

4. 15KW small high-frequency welding equipment The induction heating brazing machine can be used for welding metal parts, such as: towel racks, soap nets, bath towel racks, auto parts, motorcycle parts, metal terminals, small hardware, electric heating pipe fittings and fasteners, etc. Advantages for brazing metal parts:

1. Induction heating is fast and efficient

2. Power saving and low cost

3. Multiple workpieces can be welded at one time, which greatly improves the welding efficiency

4, the oxidation area is small,

5. Uniform heating, no missing soldering and missing solder joints

6. The welded workpiece looks beautiful and firm.

5. 15KW small high-frequency welding equipment Induction heating brazing machine can be used for tin welding of small metal parts, such as: The advantages are:

1. Induction heating speed is fast, high efficiency,

2. Energy saving and electricity saving, low cost and less electricity consumption.

3. Multiple workpieces can be welded at one time, with a high degree of automation, which greatly improves the welding efficiency

4. No oxide layer due to low heating temperature

5. The heating is uniform, and the welding seam is full, beautiful and firm after welding.

浙公網(wǎng)安備 33038102331513號

浙公網(wǎng)安備 33038102331513號