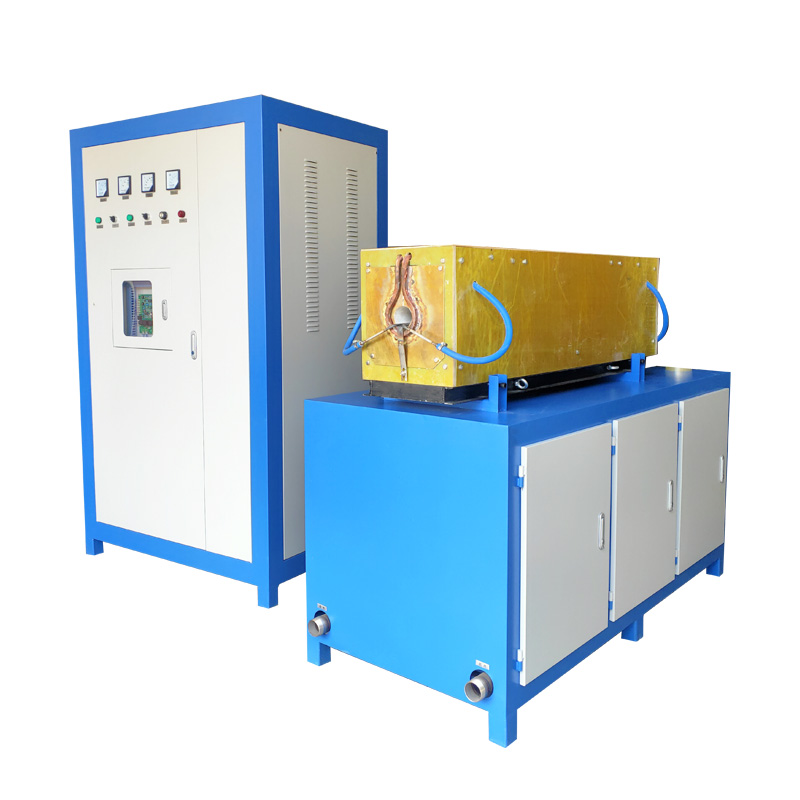

RAZ-35KW medium frequency power supply 10KG stainless steel and iron melting furnace

The intermediate frequency melting furnace is used for melting and heating of steel, stainless steel, copper, aluminum, gold, silver and other metal materials; the melting capacity ranges from 1KG to 200KG.

The basic composition of the intermediate frequency melting furnace:

Including intermediate frequency power supply, compensation capacitor box and melting furnace. According to different application requirements, it may also include infrared thermometers, temperature controllers and other devices; smelting furnaces are divided into three types: tipping smelting furnaces, top-out smelting furnaces and stationary smelting furnaces. The tipping type melting furnace can be divided into mechanical tipping furnace, electric tipping furnace and hydraulic tipping furnace according to the tipping method.

Features of intermediate frequency melting furnace:

1) The intermediate frequency melting furnace is used for the melting of steel, stainless steel, copper, aluminum, gold, silver and other materials.

2) The medium frequency smelting has a good electromagnetic stirring effect, which is beneficial to the uniform temperature and structure of the smelting metal, which is beneficial to scum and reduce impurities;

3) The frequency range is wide, from 1KHZ to 20KHZ, and the induction coil and matching compensation capacitor can be designed by comprehensively considering the melting volume, electromagnetic stirring effect, heating efficiency, noise during operation and other factors to determine the output frequency;

4) Energy saving than thyristor intermediate frequency;

5) The equipment is small in size and light in weight, and the melting capacity ranges from several kilograms to several hundred kilograms.

6) Gold melting machine

It is mainly through the process of smelting, purifying, casting and other processes after instantaneously inducing the temperature of the precious metal to the crucible container.

1. For precious metals: platinum, palladium, gold, silver, copper, steel, gold powder, sand, and other high melting point metals for melting.

2. The amount of metal to be melted in a single time is 1-5KG, and the melting time of a single time is 3-8 minutes.

3. The furnace temperature can reach 1500-2000 degrees.

Precious Metal Melting Furnace:

It is mainly through the process of smelting, purifying and casting that the precious metal is instantly heated by induction heating through the crucible container.

7) The technology of this product is the best technology in the market. It brings together the scientific research achievements of many well-known experts at home and abroad, and successfully converts and upgrades from electron tube technology → transistor MOSFET technology → IGBT module technology.

All models are equipped with IGBT module technology, so that the product stability can be better! Continuous pursuit, cooperate with schools and research institutes for small-scale smelting use.

Main melting furnace specifications and heating capacity:

The heating capacity of each melting furnace is listed in the table below. When the furnace is cold, the melting time of each furnace is 50--60 minutes, and when the furnace is hot, the melting time of each furnace is 20--30 minutes.

Furnace Specifications | input high power | Melting capacity of common smelting |

| Iron, Steel, Stainless Steel

| Brass, Copper, Gold, Silver | Aluminum and aluminum alloys |

RAZ-15melting furnace | 15KW | 3KG | 10KG | 3KG |

RAZ-25melting furnace | 25KW | 5KG | 20KG | 6KG |

RAZ-35melting furnace | 35KW | 10KG | 30KG | 10KG |

RAZ-45melting furnace | 45KW | 18KG | 50KG | 20KG |

RAZ-70melting furnace | 70KW | 25KG | 100KG | 30KG |

RAZ-110melting furnace | 110KW | 50KG | 150KG | 50KG |

RAZ-160melting furnace | 160KW | 100KG | 250KG | 100KG |

浙公網安備 33038102331513號

浙公網安備 33038102331513號